We build optimal systems for pump equipment using a range of simulation technologies.

We apply our own simulation technology to siphon piping such as discharge pipes for drainage pumps and propose quick siphon formation.

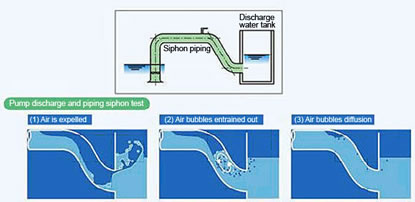

When the pump is started under the siphon piping, air is forced to be ejected, the air bubbles are then entrained out and finally the bubbles are diffused. The siphon will then be formed and the pump will operate normally. Quick siphon formation is important to fully bring out pump performance.

Pump discharge and piping siphon formation

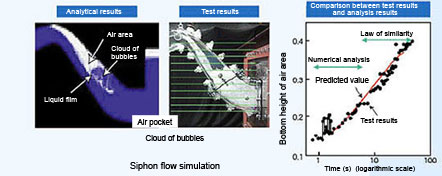

We have compared the analysis and test results for the rectangular siphon piping, as shown below, and have confirmed that our test and analysis results match.

Analysis using scaling

Contact us from here.