Appropriate maintenance and servicing are essential for maintaining the functionality of pumps. Please use our diagnosis technologies.

Internal inspections with an underwater camera and endoscope camera and ultrasonic corrosion diagnosis are effective for monitoring deterioration conditions and abnormalities inside an installed pump. We collect data that will serve as the criteria for overhauls and update planning and contribute to early detection of causes of abnormalities by providing highly reliable diagnosis and measuring technologies that are used in various tools, including analysis and inspection equipment.

The maintenance and diagnosis technology shown here is equipment diagnosis technology for pumps that are in service. However, you can select technology that is most suitable to your maintenance needs based on managed trends and comparisons with standard data (design valve) at the time of pump installation.

We also combine technology to provide versatile diagnosis results, optimal energy conservation and a longer service life to offer you a one-stop solution service with minimal life cycle costs.

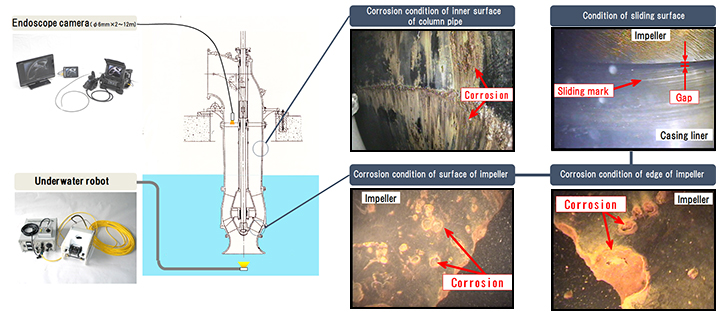

Internal parts of the pump such as impellers and casing liners can be checked by inserting an underwater camera (robot and endoscope) into the pump.

(Working conditions such as dirty water and the amount of foreign material sticking to the parts could obstruct the equipment's view.)

Underwater robot

Endoscope camera

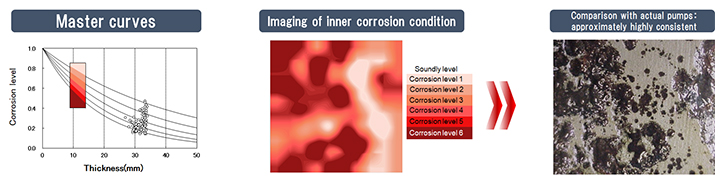

The measuring equipment consists of an ultrasonic flaw detector and a pen PC.

We can travre the corrosion condition and thickness of the cast-iron pipe from the outer surface of the pipe to the inner surface using ultrasonic waves processed through the PC.

Corrosion diagnosis system

Vibroscope, sound level meter, FFT analyzer, data recorder, PC/printer, and analysis related software, corrosion diagnosis system (ultrasonic wave), industrial endoscope camera, chlorine ion densitometer, tank thickness diagnosis equipment, internal pump inspection equipment, AC 100 V self-powered supply equipment (power generator) equipment, etc.

All the measuring equipment and the diagnosis vehicle

The examples below are images of the external conditions of the inner surface of the column pipes, bearing bracket, casing (guide vane), impeller and casing liner of the installed pump.

We can check the corrosion and wear of the impeller and casing liner, the existence of foreign matters, etc. visually by photos.

By means of ultrasonic measurement, the corrosion and thickness on the inner surface of the pipe channel are identified and estimated visually in 2D images as spatial distributions.

The diagnosis results are actual with the material on the inner surface.

Contact us from here.