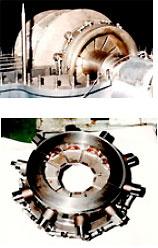

The following is an introduction to technology for converting from rotors to high-efficiency impellers and for modifying capacity control from suction valve to inlet vane, as a measure to support energy efficiency to prevent global warming.

The efficiency of new impellers developed in 2001 has been further increased, so efficiency improvements of 5 to 10% have been achieved compared with blowers supplied prior to 1982.

(In-house comparison)

Capacity control over a wide range has been achieved by the combination of the optimal inlet vane design and high-efficiency impellers.

Good capacity control under partial load can be achieved using an inlet vane flow rate control device provided on the impeller inlet.

( In case of discharge pressure control is invariable)

Contact us from here.