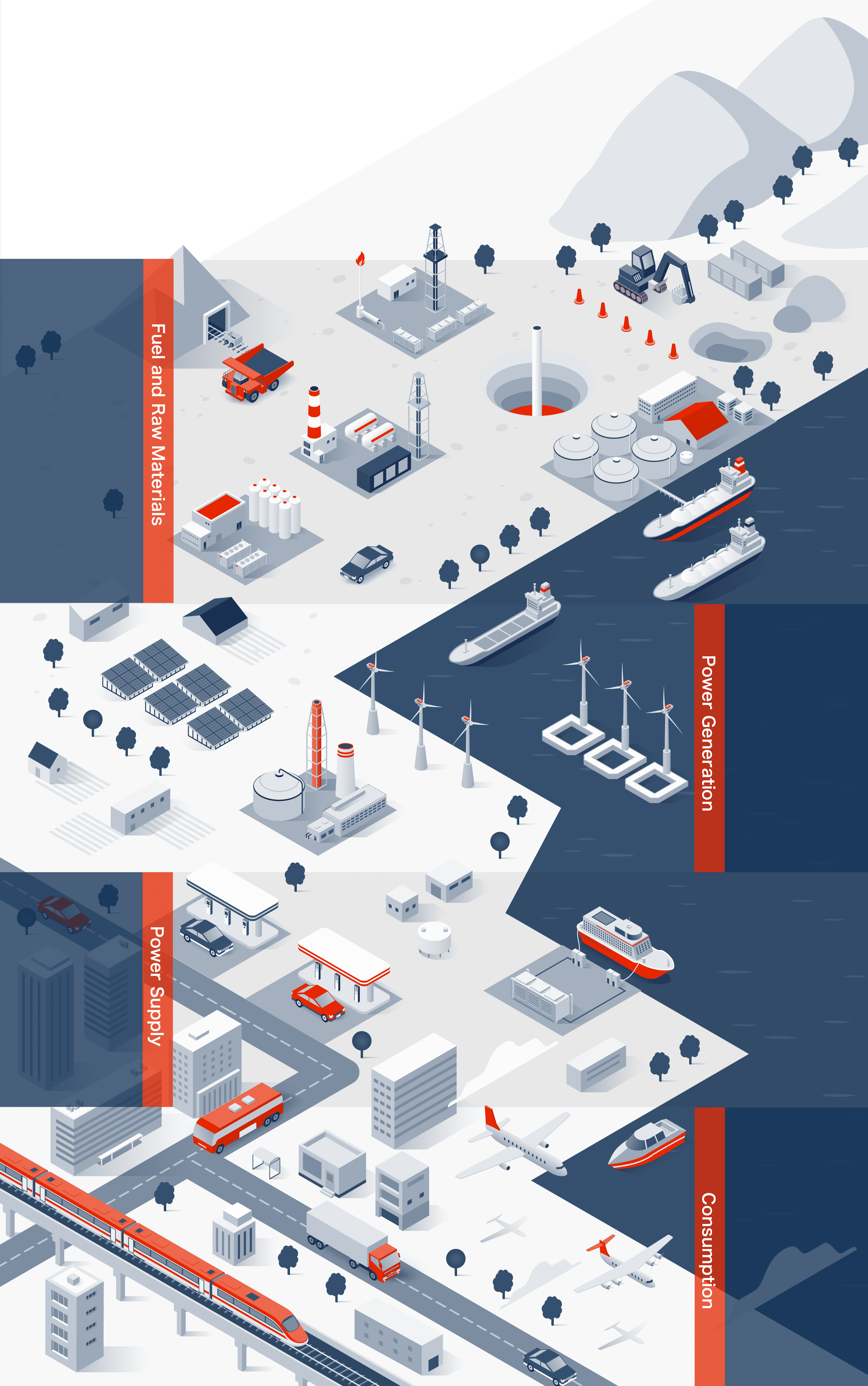

As the international trend grows for decarbonization, Hitachi Industrial Products realizes a carbon-neutral society by "providing Products & Services that reduce environmental loads" as a company that creates environmental value through industrial activities in society, including fuel and raw materials, power generation, power supply, and consumption.

Water Electrolysis Plants

Water Electrolysis System

Related Products:

Inverter

Auxiliary System

CCS (Carbon Capture and Storage)

Underground CO2 Storage

Underground Storage System

Receiving Terminals

Pump Drive System for

LNG/Ammonia/Hydrogen

shipping and receiving terminals

Ammonia Carriers

Ship Auxiliary System

Related Products:

Motor

Inverter

EV/Fuel Cell Construction Machinery

Electric Drive System

Related Products:

Motor

Control Panel

LNG Carriers

Ship Auxiliary System

Related Products:

Motor

Inverter

LNG/Coal-fired Power

Environmentally friendly

Fuel-Fired Power System

Solar Power

Solar Power System

Related Product:

PCS (Power Conditioning System)

Onshore Wind Power

Wind Power System

Related Products:

Generator

PCS (Power Conditioning System)

Offshore Wind Power

Wind Power System

Related Products:

Generator

PCS (Power Conditioning System)

Charging Stations

Charging System

Related Product:

Port Facilities

Onshore Power Supply

system for Ships

Fuel Cell Rolling Stocks

Railway Drive System

Related Product:

Motor

Fuel Cell Buses

Drive System

EV/Fuel Cell Trucks

Drive System

Hybrid/Hydrogen

Aircraft

Aircraft Drive System

Hybrid/Fuel

Cell/EV Ships

Ship Drive

Equipment

Electric Aircraft

Aircraft Drive System

Hitachi Industrial Products provides Products & Services that promote Electrification and reduction of CO2 emissions for customers' environmental value.

Dump Trucks are active in the global mining fields. By providing Drive System with motor & inverter, we contribute to the driving and control performance and the environmental performance, such as reducing CO2 emissions through Electrification.

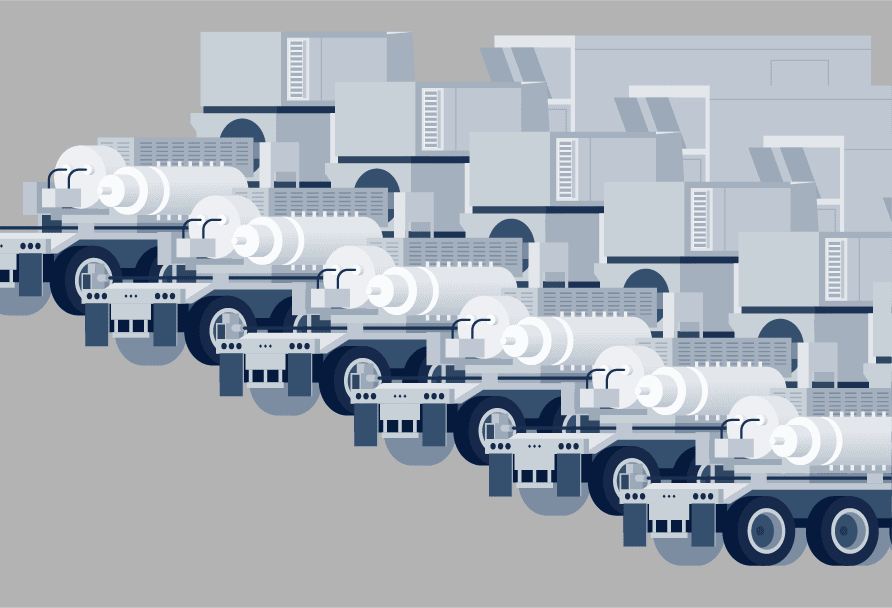

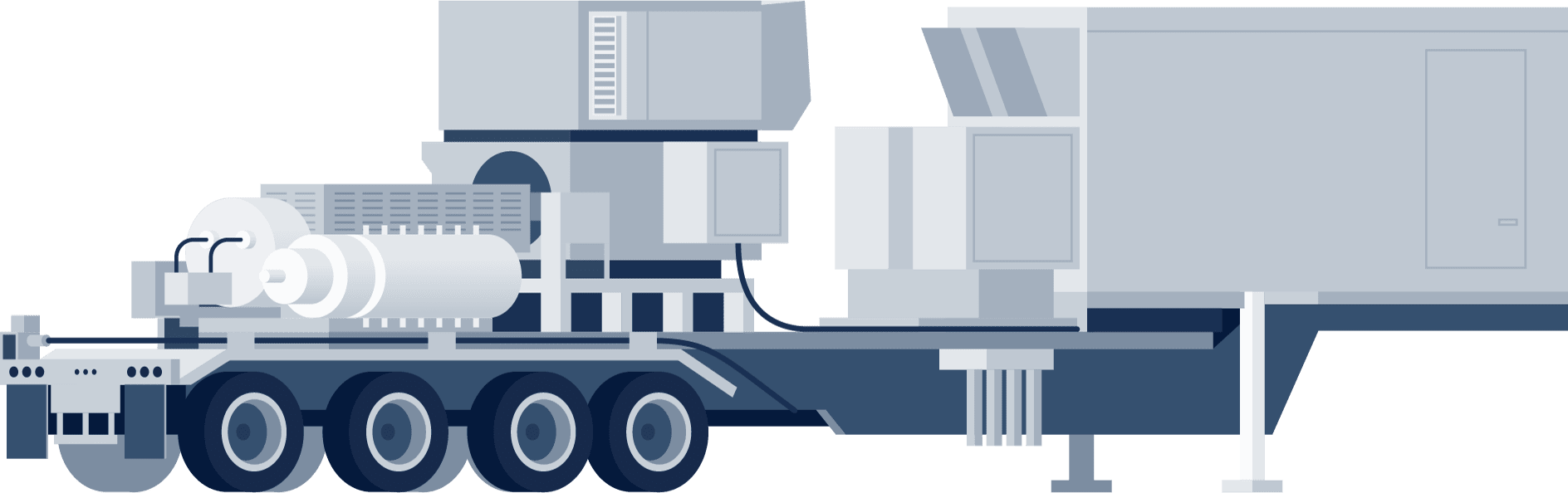

Fracking is an essential field activity in the shale oil and gas production process. Electrification of Fracking Fleets by utilizing variable speed drives in combination with electric motors improves performance and has positive environmental impact, including CO2 reduction and energy savings.

Achieving a decarbonized society by 2050 requires rapid EV adoption along with the expansion of charging infrastructure. Our Multi-Port EV Charger supports high-capacity, simultaneous charging, significantly reducing charging time and alleviating congestion at charging stations.

It is also compatible with V2X* technology, enabling EVs to function as energy storage systems and contribute to grid stability.

*V2X (Vehicle to Everything): The supply of power from EVs to a wide range of devices and systems.

By maximizing the value of EVs as distributed energy resources, our multi-port charger helps accelerate CO2 reduction and supports the transition to a carbon-neutral society through efficient, intelligent charging.

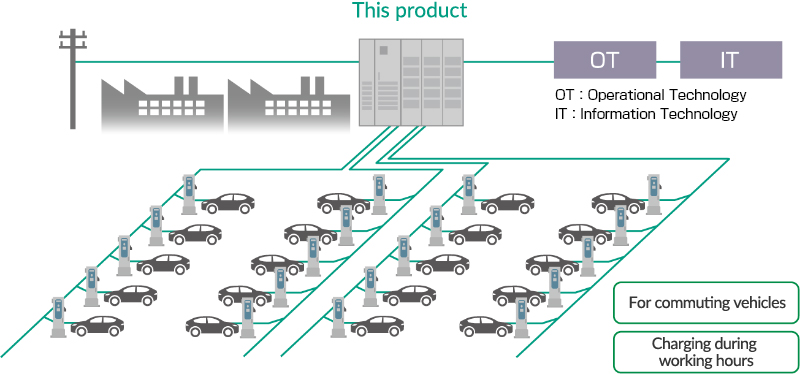

By installing multi‑port EV chargers in workplace parking areas, employees can charge their EVs during working hours, helping to reduce CO2 emissions from commuting vehicles—classified under Scope 3, Category 7.

*"Workplace E‑Powering" is a registered trademark of Hitachi Industrial Products, Ltd.

Ammonia is expected to be an alternative fuel for coal-fired power generation plant as it does not emit CO2 during combustion. Our compressors have rich delivery records and global experience, and contribute to reduce CO2 emission.

CCS* is a technology to capture CO2 emitted from industrial processes, such as steal and cement production, or power generation, and to store CO2 underground in geological formations. CCS is also applied to capture CO2 at production of blue hydrogen or blue ammonia. Our CO2 compressors for CCS contribute to reduce CO2 emission.

*CCS: Carbon dioxide Capture and Storage

Driving and control systems that drive an alternator with an engine and supplies the generated power to wheel motors via a control cabinet. Dump Trucks are active in the global resource mining fields, to improve the driving and control performance, maintainability, and reduce operating costs. these also contribute to the improvement of environmental performance, including the reduction of CO2 emissions.

In particular, Dump Trucks with trolley system receive power directly from the pantograph under overhead lines and improve driving performance with reduced engine load and is contribute greatly to reducing fuel consumption and CO2 emissions by improving.

Alternator

Wheel motor

Control cabinet

Hydraulic fracturing is a modern technology used for well stimulation involving the fracturing of gas/oil laden bedrock formations by the process of injecting water, sand, and other proppants. In lieu of legacy diesel driven systems, the Electrification of Fracking Fleets utilizing variable speed drives in combination with electric motors improves performance, allows significant energy savings, and achieves positive environmental impact including CO2 reductions.

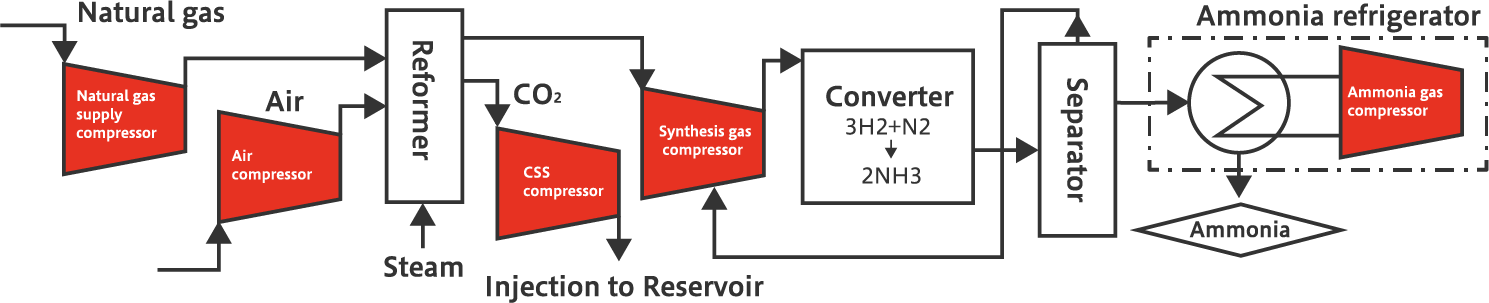

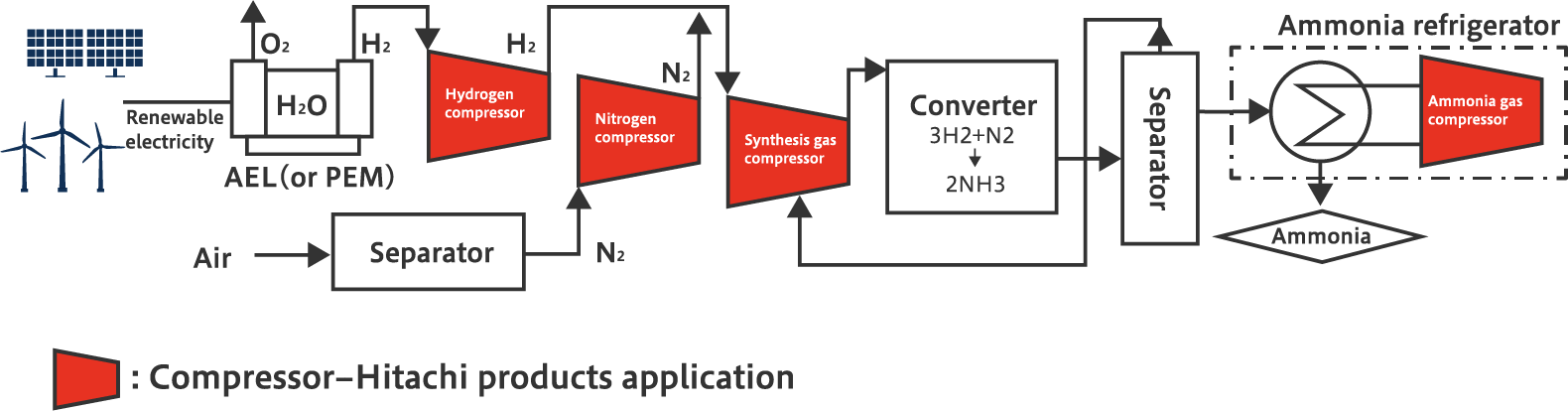

Since ammonia does not emit CO2 during combustion, it is expected to become an effective means of carbon neutral in the future by promoting the use of ammonia as an alternative fuel for power generation and marine fuel.

Ammonia is produced by synthetic reaction of hydrogen and nitrogen, but a large amount of CO2 is also generated when hydrogen is produced by decomposing the hydrocarbon of the raw material.

Blue Ammonia*1 and Green Ammonia*2, which do not emit CO2 in atmosphere in ammonia production process and are known as clean fuel, are going to be widely introduced soon.

We will contribute to reduce CO2 emissions by supplying compressors to the Blue & Green Ammonia plants.

*1 Blue Ammonia : Ammonia produced without CO2 emission in atmosphere by CCS and so on, against CO2 produced in the conventional ammonia production process.

*2 Green Ammonia : Ammonia produced by renewable energy

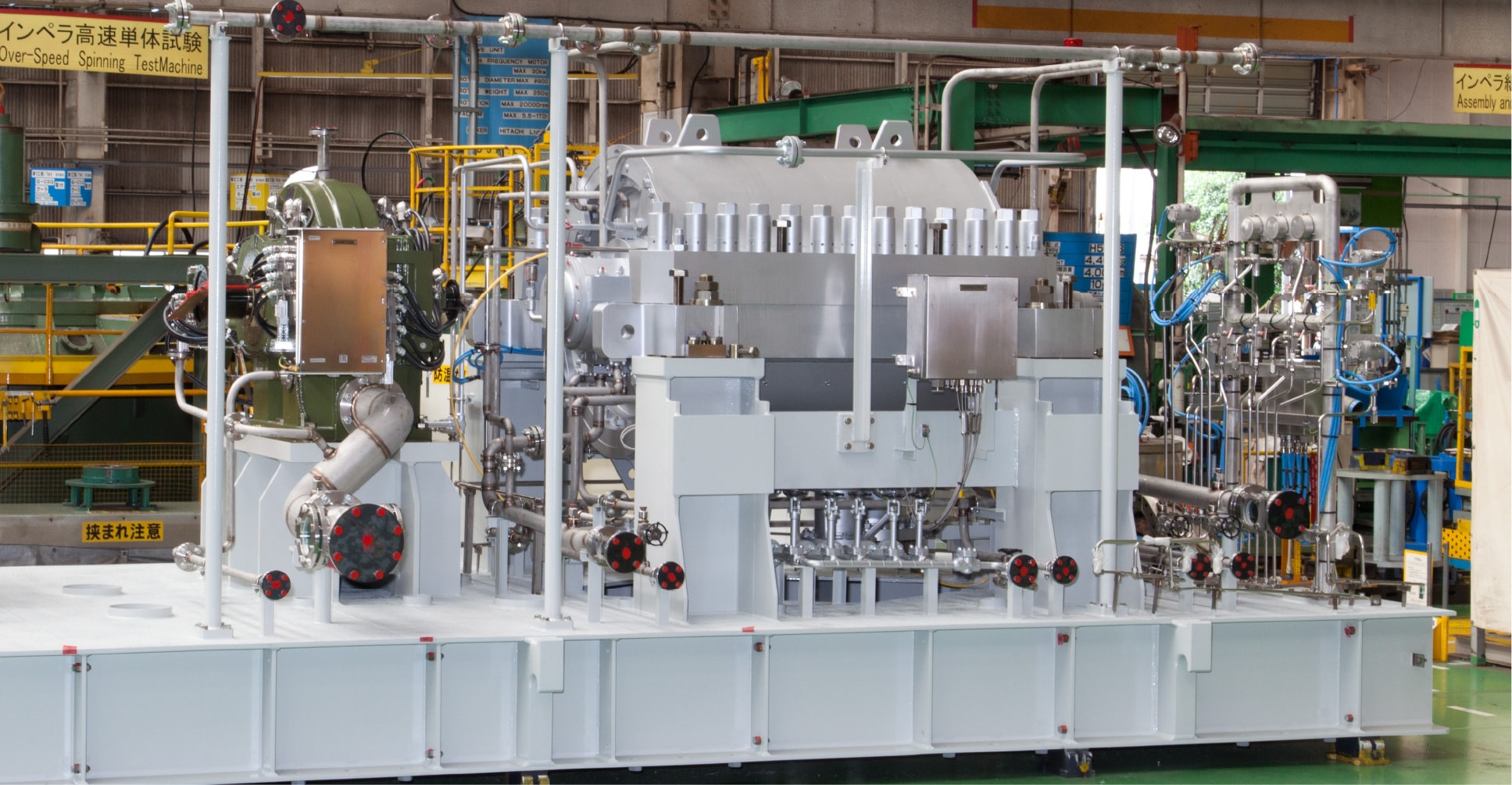

Blue Ammonia Plant

Green Ammonia Plant

For realization of a carbon-neutral society, global shift from engine vehicles to electric vehicles (EVs) is underway. However, there is a urgent need to expand charging infrastructure as congestion in charging area frequently occurs in highway and parking areas. as the number of EVs with large capacity batteries and large commercial EVs is expected to increase in the future, there is a need for EV chargers that meet these quick charging requirement. Large capacity, Ultra fast, Multi-Port EV Charger developed by Hitachi Industrial Products is capable to satisfy these requirements supporting V2X*1 compatibility enables EVs to be used as storage batteries, and contributes to grid stabilization.

*1: V2X (Vehicle to Everything) is a power transfer technology that connects vehicles with various items for mutual linkage.

By installing a multi‑port EV charger capable of connecting up to 80 vehicles and charging 20 simultaneously in our workplace parking area, we have introduced a system that allows employees to charge their EVs during working hours. This creates an environment where employees can use EVs even without home charging facilities, enhancing employee satisfaction while promoting CO2 reduction from commuting.

Furthermore, we aim to expand these efforts to include energy management and integration with local power networks, accelerating our initiatives toward achieving carbon neutrality.